Thanks to the "EASY-START" exclusive hydraulic system there is no need to clear the die's holes by using drills or pins.

The "LOAD SENSING" hydraulic system allows to monitor each production phase and to protect the die group from damages and breaks!

Thanks to the hydraulic automation the P-300/P-500/P-700 Series adapt automatically to the raw material without need for any manual mechanical change. You only need to provide the raw material, while our machines will transform it into pellets!

The hydraulic system allows the production of pellets* with a wide range of wood types, biomass and plastics (* Ø 6 and Ø 8 pellets in accordance with the UNI EN 14961-2 PLUS A1-A2-B regulation, similar to the Ö NORM and DIN-Plus regulations).

Production costs reduced by 75% compare to mechanical machines!

Guaranteed pay-back of the initial investment within less than 12 months!

The exclusive operative characteristics of the P-300/P-500/P-700 Series allow to obtain a high production with the lowest Euro/Ton of pellets ratio.

- Project and research to make pellets and briquettes!

- We guarantee a homogeneous drying degree apart from the moisture percentage of the entering material!

- The drying type has been planned not to modify the material’s characteristics and contents. The coming out material is ready to be transformed into pellets and briquettes!

- The crashing and mixing characteristics make uniform the coming out raw material size!

- Very easy use. The automatic cycle is regulated by one button whose parameters are immediately displayed on the PLC!

- The dryer is assembled and started a few hours after the delivery!

- Very low installation expenses, since we need only one P System technician during the assembling and start-up assistance!

- Assistance by INTERNET (INTRANET)!

- Exclusive project giving the best output of the market!

- Fire safety thanks to the indirect use of the heating source and the low working temperature inside!

- Our system respects the rules in force about the safety and the dust emissions in the atmosphere thanks to our wide range of filtering systems!

- Automation by high quality hydraulic components and reliability!

- Recycling in production of all the dust made by the installation!

- World Exclusive!

- Min production from 100 kg/h!

Dryers

Planning and study aiming at pellettizing and briquetting Warrant of homogeneity in the drying degree, independently of the difference in the...

Leggi tutto

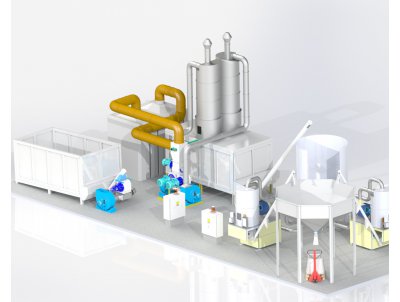

Complete pellet installations

Hydraulic plants fully automated for pellet production Unique hydraulic system to pelletize and dry Operating expenses 50% less than the other...

Leggi tuttoSome of our products

Worldwide exclusive, only one roll with hydraulic loading control (fail safe). The "LOAD SENSING" hydraulic system allows to monitor each production phase and to protect the die group from damages and breaks!

From chips to bagged pellet by only one supplier

P SYSTEM S.r.I. was founded in 1 995 by a staff with a long experience in the supply of hydro-dynamic industrial automation. After developing the dynamics of the hydraulic briquette presses in the Nineties, the company P System S.R.L. started to design a new production line for pellets aiming to supply TURN KEY installations through the “PLUG AND PLAY” system. The technology applied by P System has remained the most productive and modern

Our fully automated production plants include:

- SILOS FOR LOAD MATERIAL

- DRYING

- PELLETIZING

- PACKAGING

- TRANSPORT LINES AND FILTER AIR

We supply products and systems CUSTOMIZED for every need.

AUTOMATIC SYSTEMS OF PELLETIZATION AND DRYING ESPECIALLY FOR SAWMILLS.

AUTOMATIC SYSTEMS OF PELLETIZATION AND DRYING ESPECIALLY FOR COGENERATION PLANT.

AUTOMATIC SYSTEMS OF PELLETIZATION AND DRYING ESPECIALLY FOR PACKING INDUSTRY.

AUTOMATIC SYSTEMS OF PELLETIZATION AND DRYING FOR WOODWORKING FIELD.

AUTOMATIC SYSTEMS OF PELLETISATION AND DRYING FOR THE AGRICULTURAL SECTOR (STRAW)

AUTOMATIC SYSTEMS OF PELLETISATION AND DRYING FOR SAILING.

Clients Testimonials

Latest News

PROGETTO FUOCO FAIR 2020

January 30, 2020WE WILL BE PRESENT AT THE FAIR PROGETTO FUOCO 2020 IN VERONA - 19th TO 22nd FEBRUARY 2020 YOU CAN FIND US IN PAVILLON 3 AT THE STAND B6

BRAUN Maschinen FAIR

November 17, 2017We would like to inform You that P System will exhibit at the BRAUN Maschinen fair in Gerestried (Germany) , 24th to 26th November 2017. Come to see

Interview at Greenenergy Expo 2009 at Milan

March 31, 2010Interview with Mr. A. Saltups: the new generation of hydraulic plants for pellet production.